Did you ever feel afraid when viewed a huge Crane doing the action of back and forth while lifting heavy stuff? You watch the whole thing unfold entirely concerned, and now it finally ends on a big cliffhanger. You are not alone! Seeing a crane sway makes many people nervous. This swaying can be extremely dangerous and can lead to accidents if the crane is not controlled properly. But don’t worry! TPTECHOIST has the Answer: Anti Sway Crane Technology

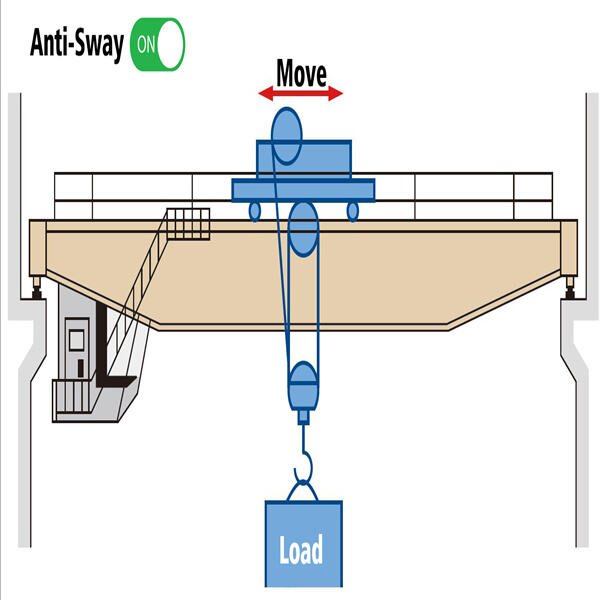

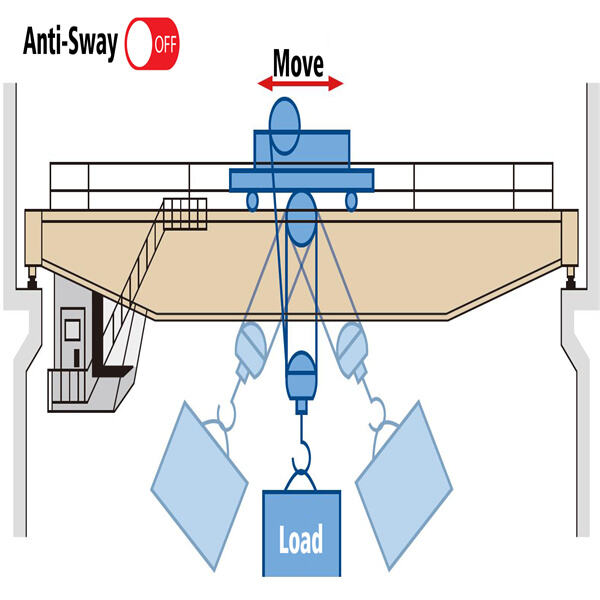

The Anti Sway Crane Technology is a feature which can be used as part of crane safety to counter act a dangerous sway when picking up heavy objects. It features distinct sensors that can sense every movement present in the crane. Improvements in crane technology and higher-quality sensors make these things quite intelligent, which helps the cranes determine how to stop swaying. This means the crane can be in only one spot; It does not swing in turn, it is safe for workers in its proximal vicinity.

Wherever the work is happening—one key place being overhead with cranes—the number one priority is safety. We are doing everything we can to keep everyone safe. This is important n not just for the safety, but it also makes the job easier because it can prevent accidents that might lead to delays. With safe operation of the crane, work can be done faster and better. The reason is because TPTECHOIST guarantees a safe but faster lift with the well-known Anti Sway Crane Systems.

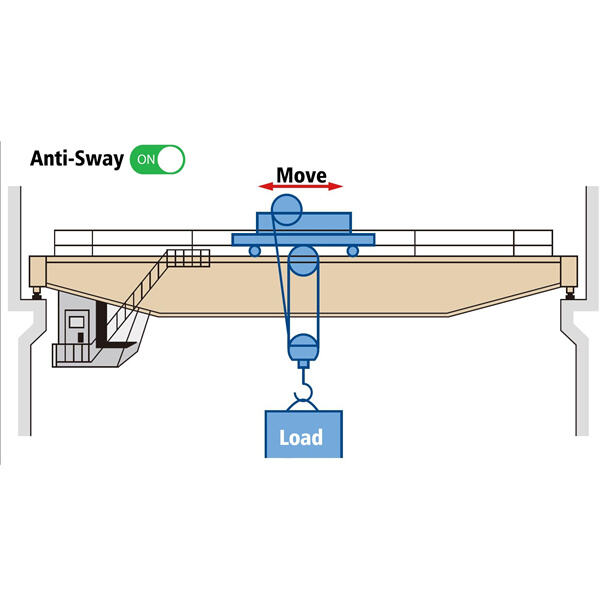

Anti Sway Crane Systems is a smart technology that keeps the crane static while lifting heavy material. This speeds the lifting up and gives the operators a much easier lift because the crane does not swing. The crane can lift things much more speedily and effectively when it was stable. Not only that, but it implies fewer staff is required to assist with lifting as they can deal with various other responsibilities.

The cranes are equipped with certain features that facilitate the operator to control the crane more efficiently and effectively. For example, they feature joystick controls that offer exceptional precision to crane operators. In addition, there are the fine tuning adjustments to make everything perfect and controls that allow operators to move the crane from a distance. All these features are useful as when the crane is handled with these, it can easily lift heavy things more accurately and safely. This control allows you to lift heavy loads, move them all around the worksite without fear of dropping a load and causing bad accidents.

By utilizing an Anti Sway Crane Solution, the technology can sense any sway from the crane. The software quickly calculates the most effective way to ensure that when sensors perceive movement, the crane keeps it steady and sway to a minimum. It makes the activity much safer and reduces the risk of any accidents. Moreover, they assist the operators control it much easier that save lots of time and efforts during the crane lifting tasks. That will all work of they can get their jobs done without a thought to things going wrong.

One of these is the accurate controls we spoke about. This means that this crane can be controlled very precisely. Other awesome feature you can shift control of the crane from a distance, this is helpful. And the remote access is used for lifting safely and correctly even in challenging places where getting near to the crane may be complicated. Further, Anti Sway Cranes can be configured to handle various lifting tasks so that they are suit for many different operations. They are versatile, so they can use for nearly any job and thus need more skilled labors to do their day to day tasks that increase overall productivity.

With a wide range of products, Toptech caters to a wide array of needs for anti sway crane handling, from small workshops to large-scale industrial facilities. Our product range includes overhead cranes, electric hoists and crane parts such as end the carriages, busbars for cranes, etc. Toptech is constantly updated with the latest technology and innovative designs.

TOPTECH can provide customized solutions that anti sway crane our customers' specific operational requirements. We know the distinct requirements of different industries and offer tailored products that conform to the specific requirements of functionality and performance.

TOPTECH provides comprehensive services to help our clients to get the most value from their equipment. This includes maintenance, anti sway crane, spare parts and technical support. We also provide education and assistance to improve operational efficiency and safety.

The expertise of TOPTECH's engineers allows us to create high-performance and robust crane systems We anti sway crane cutting-edge engineering techniques and advanced technologies such as intelligent control systems synchronized lifting methods and even synchronized controls into our product design and manufacturing processes