For what are known as overhead cranes, availability of special machines which serve to lift and move heavy things in factories or warehouses etc. These TPTECHOIST overhead crane parts are important because their purpose is to help with the handling and transportation of large, bulky materials that would be very difficult or impossible for anybody (or even a group) of people to move. But, a lot of people do not look beyond the price that it costs to purchase and operate these cranes. Today we will focus on costs of overhead cranes in detail. We will also find out why they are so costly, the expenses that people overlook in terms of a hidden cost common to such cranes, alternative lifting solutions available elsewhere When it comes to saving on their use and location from where we can calculate owners real costs.

An overhead crane cost can vary due to several factors. Type of Crane You Need The very first thing to consider is what type and how many cranes you require. There were many different types of cranes particularly bridge, gantry and floor or jib cranes. There are some things that all warriors share in common, and other unique features of each type, which have different costs associated with the kind they are. The next factor you need to look at is the weight that crane have a capability of lifting. The larger the lifting capacity and load, it also will be more money.

Third big factor: how deep the crane can go Common it will have a heavier price tag too if the crane needs to be able to reach further throughout its working envelope for lifting and moving materials. The penultimate one is what height does the crane have to elevate things. The higher it has to lift things up in the air that will mean more cost of course. The last fifth thing you will want to think about is the type of work that it crane do. That said, there are jobs that would utilize heavy duty cranes due to their nature (eg construction or manufacturing), whereas other contexts including farming and smaller workshops might require lighter potable models just as effectively.

The cost of an overhead crane is not only the money you pay for when buying a cranes. There are also additional, less obvious costs to consider as well (which then chronically add up over time). The first one is the cost to purchase and install crane. This involves funding skilled and experienced people to actually do it properly. Step 2 is maintenance, which simply means checking the TPTECHOIST overhead crane kits on a regular basis to ensure it's still operational. This post covers the steps you may need to take in order to mend a noisy garage door, as well replace additional worn out parts that would otherwise be quite pricey. 3) The third is that you need to train workers for safe use and maintenance of the crane. The most important is to avoid serious accidents by using well-trained operators who know exactly how they should use the machine.

For instance, forklifts are usually less expensive to buy and operate but they may not be able of lifting as much material in comparison with the overhead cranes. They are designed for transferring items in a warehouse but will not be the best way to do heavy lifting at all. It is significantly more affordable to utilize hoists or conveyor systems, however they do not possess the versatility of overhead cranes in regard to moving materials from one place to another horizontally. While more expensive to buy and maintain, overhead cranes boast the ability to lift heavier weight as well as do so many things.

Third, routine checks and maintenance can spot problems early. Doing so can prevent bigger issues that may result in costly repairs down the road. Fourth, the use of the crane is most efficient in eliminating downtime. This consisted of using the crane only when absolutely necessary so as to not overload it leading to crashing. Then, by upgrading certain components of the crane you can increase its performance and efficiency so that it uses less energy than before which will save your company money in the long run.

Material Handling & Mechanical Overhead crane ownership costs When it comes to the ultimate cost of owning an overhead crane you have to factor in more than just what was cheaper upfront or even over its service life – but also hidden costs as well. That includes not only the purchase price for you to buy the TPTECHOIST overhead crane but also should be considering through installation charges, ongoing maintenance fees (which are often avoided in traditional servicing), energy consumption as a cost and fixing costs when it breaks down. You will also want to estimate how durable the crane is and when it may need maintenance, repairs or even replaced.

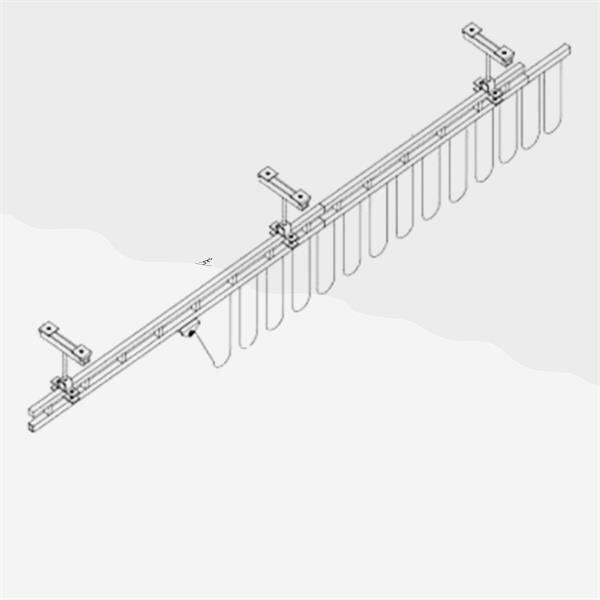

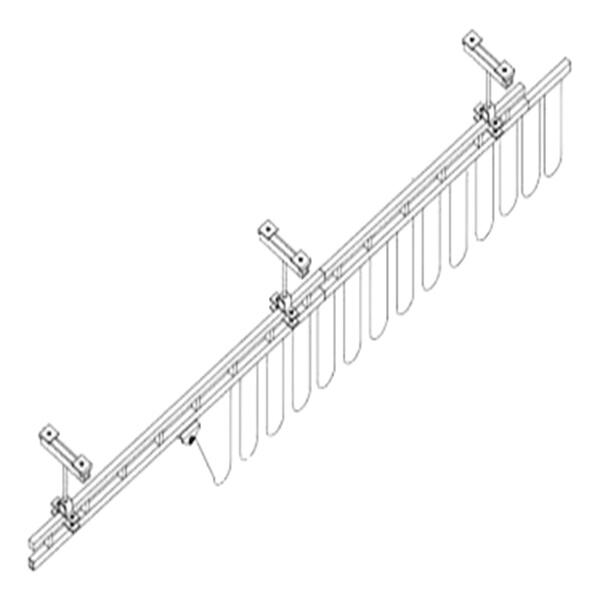

Toptech provides a range of solutions to meet needs of handling materials for small workshops and large industrial facilities. The range we offer includes a variety of Overhead crane cost, gantry cranes, electric hoists, crane components like end carriage, crane busbar, etc. Toptech is constantly updated with the latest technology and cutting-edge designs.

Our engineering expertise at TOPTECH allows us to design high-performance reliable crane systems that are reliable and high-performance Our product design and manufacturing process incorporates cutting-edge engineering concepts advanced technologies as well Overhead crane cost intelligent control systems like controlled lifting synchronized and intelligent control systems

TOPTECH offers a wide range of Overhead crane cost to help our customers get the most out of their products. This includes maintenance, installation, spare parts and technical assistance. We also provide training and consulting to improve operational efficiency and safety.

TOPTECH can provide customized solutions to meet the specific requirements and operational Overhead crane cost of our customers. We offer products made to fit the specific needs of different industries.