Overhead Travelling crane: This machine is usually used in factories, construction sites and warehouses. This allows items to be moved by one or two workers quickly, rather than a team of many. This makes things faster and much more scalable. A brief on the Overhead Travelling Crane and how does it work?

Their great strength is that they can lift things. Big heavy things to be more precise and accurate up to thirty-five tons, barely smaller than an elephant. This sheer strength also makes the TPTECHOIST hoist crane 2 ton extremely necessary in areas like factories or warehouses where without the same, an employee would spend minutes upon hours straightening with other types of welding. These cranes replace hard manual labor that is both exhausting and dangerous with the ability to quickly and safely lift a wide array of objects. This leads to a safer work environment for everyone who is working in it.

Enter your overhead travelling crane which is simple to use but commands absolute concentration. The operator knows that it is always easy to manage. It has 3 important mechanisms or manners to move like lifting the items up and down, for the forward backward movement it can run on a track back forth wise also using its sets of chains while shifting their materials. Operator must maintain a good distance with the heavy load he is moving. This is done to avoid accidents and harm. So, it is essential to have skill for controlling the TPTECHOIST hoist crane 2 ton properly so that while working on the field they do maintain safety.

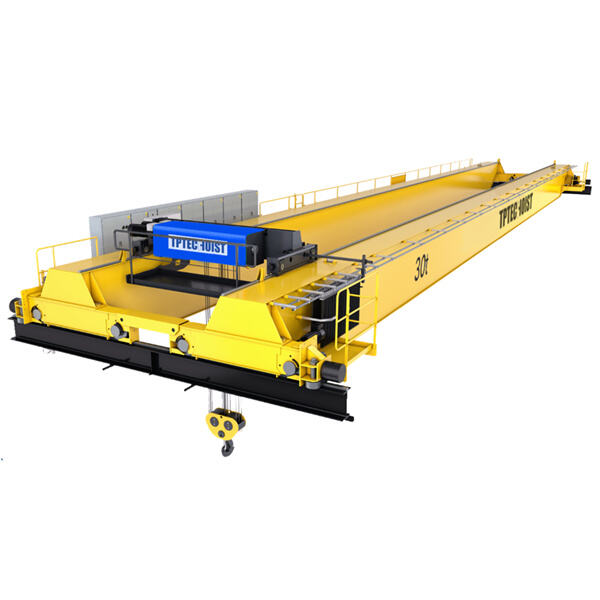

Various types of the TPTECHOIST overhead crane components can employ overhead crane and it is effective for different operations. For example, single girder cranes are smaller and able to perform lifts of up to ten tons. These are often the type of numbers you see with small plants. On the other hand, double girder cranes are much sturdier and can go up to 100 tons plus. Bridge cranes are a different form which is built up high on top of tracks to be able to take things over an outsized room. Then there are the mobile gantry cranes, used on land to pick up large containers or ships. Each crane has its specialty for a specialized job.

Amongst all other benefits, it is very crucial to preserve machines such as overhanging taking a TPTECHOIST overhead crane components properly. It provides you a guarantee that the crane is in working state and will not cause any worry or problems. There are so many items to check in the lifting components, but more likely: wheels and brakes. Electric motors and wires: Inspect every month for proper operation Every day are needed sensors that help to operate the crane. Remember, when it comes to crane operation at the job site you should make your every effort of taking service from professional technician only.

When selecting the TPTECHOIST overhead crane parts, you should know at which weight will be picked starting a course. A crane has a Rated Capacity which tells you the weight it can lift without effort. The height along with the length of boom that you desire can also be very important based upon whatever it is that will need to have completed. In addition, our crane body material count also included. As an example, steels and aluminums are typical crane materials. Choose a crane according to the above points that fulfil all of your requirements, so you can able complete task as efficiently.

TOPTECH can tailor solutions to meet our clients particular operational needs. Our products Overhead travelling crane made to fit the specific requirements of various industries.

TOPTECH offers a wide range of Overhead travelling crane to help our customers get the most out of their products. This includes maintenance, installation, spare parts and technical assistance. We also provide training and consulting to improve operational efficiency and safety.

With a variety of product offerings, Toptech caters to a wide array of handling requirements including small workshops all the way to industrial plants of a large scale. Our product range comprises a variety of overhead cranes, Overhead travelling crane and electric hoists, crane components such as end carriage, crane busbar, etc. Toptech is always up-to-date to the latest developments in technology and cutting-edge designs.

TOPTECH is backed by a deep engineering knowledge enabling us to create high-performance sturdy crane systems Our design and manufacturing process incorporates cutting-edge engineering principles as well as cutting-edge technologies and Overhead travelling crane control systems including the synchronized lifting system and the intelligent control systems